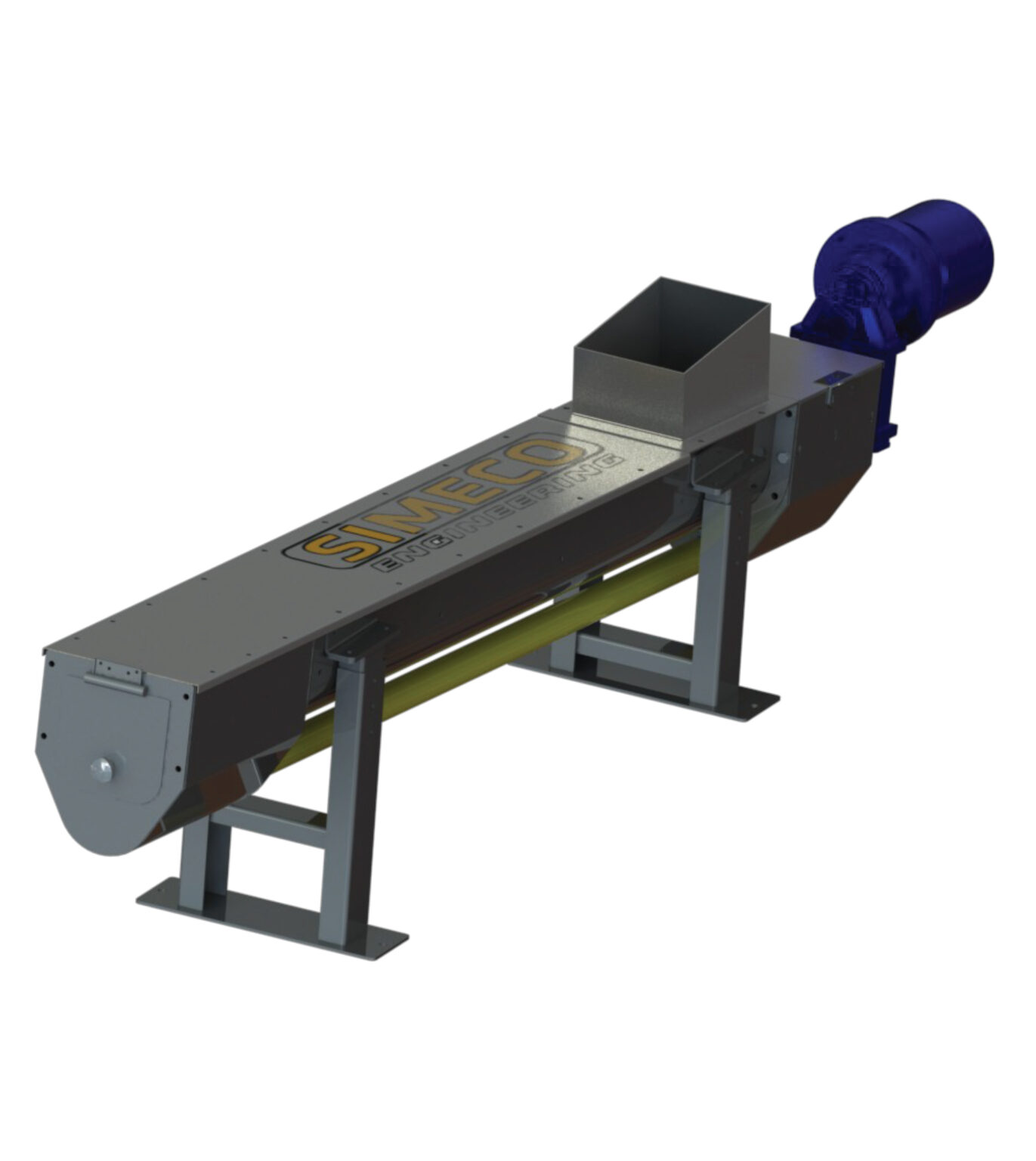

The SP Shaftless screw compactor is ma machine for screenings handling and allows to combine three operations in one single machine: draining, conveying, compacting.

The machine can be placed directly under the screen’s discharge chute or can be fed by a conveyor (spiral conveyor or belt conveyor), or by a launder channel.

The machine consists of a screw (spiral) that rotates inside a trough divided in three main sections: the draining section, usually placed before the screenings inlet hopper, where the majority of the water is discharged; the conveying section, where the material is moved toward the last section, the compacting/dewatering section, where both the volume and the weight reduction take place (up to 50%).

To increase the compaction degree, the compactor’s discharge can be provided with a spring controlled cover or with a counter weight; in some cases can be installed a discharge pipe “trunk” shaped.

The screw is usually connected directly to the drive system and a mechanical sealing unit avoid any leakages.

The working range of the machine is quite wide, ranging from 5° to 35°.

This kind of machine is mostly used when the discharge bin is far from the screen and / or when the discharge path requires both distance and slope.

The enclosure’s material of construction can be stainless steel 304 or 316, and on demand can be duplex stainless steel, while the spiral can be carbon steel, AISI 304 or 316; in some arrangement duplex spiral is also possible (please contact Simeco Engineering at the following address simeco@simecoeng.com for further information). The trough liner can be made of HDPE or UHMWPE, or sliding bars stainless steel.

The main advantages are:

• Clog free machine

• High flow capacity

• Easy maintenance

• Easy installation

Upon request the unit can be supplied provided with a control panel, which can be electromechanical or PLC controlled.